Reverse Engineering

If we study the history of the industry and how it grew in Southeast Asian countries, we will come to the conclusion that in few cases these countries have technological innovations and in almost all cases, Western and American countries have been the leaders. If we observe the country of Japan in particular, we will see that almost all the people of the world admire their products in terms of quality, but they complain that the Japanese have achieved this success by copying other people's products.

If this statement is true, if copying is a sure way to achieve the goal, what is the obstacle to doing this? This case is especially important for the developing countries or the third world due to the deep technological gap between these countries and the advanced countries of the world, and these countries should take the same approach.

• When an industrial part works well and has a high performance, a manufacturing company may decide, instead of designing from scratch, to separate that part into smaller components and analyze and model each component to improve the ability to reproduce that part. reach

• When dentists make a mold based on the shape of a tooth and produce a model similar to it.

• When a programmer, instead of designing the system and programming from scratch, analyzes a successful program or system and tries to reproduce its components.

• When the army or military organizations of a country acquire the military products of another country and try to obtain the knowledge and technology of that country through reverse engineering, or at least evaluate the scientific and technical ability of the manufacturer.

So, reverse engineering is one of the terms that has been used much more than in the past in recent decades and has even been included in public and social literature. Reverse engineering is one of the methods that companies use to speed up their product development process. This method in developing countries such as Iran, which lag behind advanced countries in terms of product design knowledge and production technology, is a response to increasing design capacity and accelerating the development process.

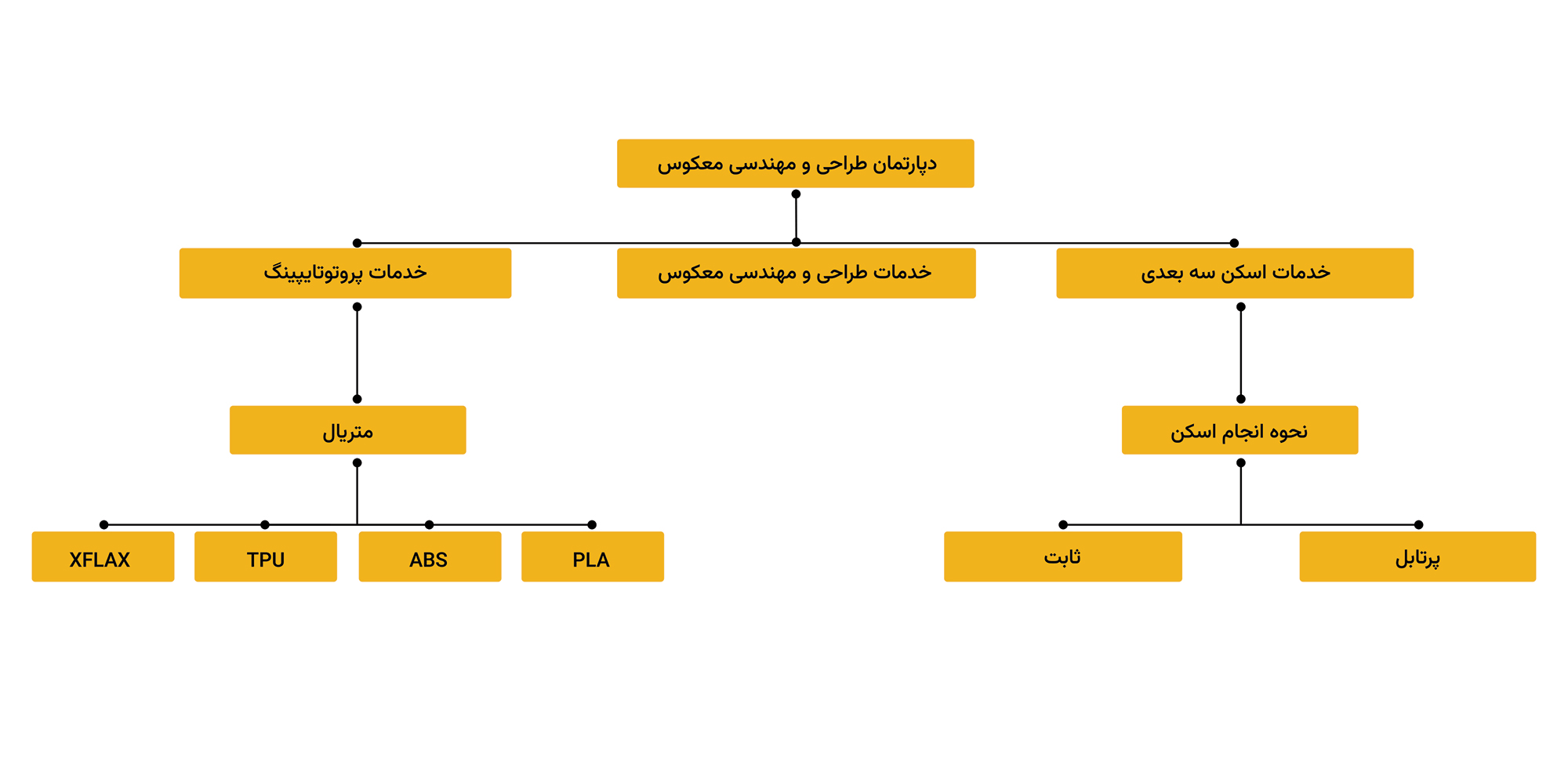

Also, today one of the main and modern methods for extracting information needed for parts and equipment in the industry is the use of new technologies, including metrology (3D scanner) and CMM method. After analysis and required technical changes using engineering design and dimensional control software such as Geomagic Control x, Geomagic Design x Solid works, Catia, 3D modeling is done, which finally extracts the dimensional information and geometric form of a piece. ; Analysis, dimensional control, modification and redesign can be used for rapid prototyping, machining, 3D printing and laser.

The measurement method by 3D scanner and CMM is used in various industries such as mining, refinery and petrochemical, wood and furniture, automobile industry, medicine, etc.; For example, in the manufacture of medical equipment, it is possible to mention the scanning of the skull of an injured person and its construction by sediment layering method (3D printing) with titanium material; In the field of animation, you can scan a person's face or body using 3D scanning and use it in the relevant software. Also, in the field of art, we can mention the making of statues and portraits of lasting faces.

At Kara Engineering Company, with the ability of specialists and experts in the field of industrial dimensioning and the presence of a precise 3D scanner with an accuracy of 0.04 mm, we are ready to provide technical and engineering services, including dimensioning, analysis, design and reverse engineering, and making prototyping samples. next) we have

Translate

Translate